Stainless Steel Reductor

Product Introduction of Stainless Steel Reductor

The Stainless Steel Reductor is a high - performance power transmission device that combines advanced manufacturing techniques with high - quality stainless - steel materials. This device is mainly composed of a stainless - steel housing, high - precision gear sets, shafts, and sealing devices. Through a carefully designed gear ratio, it converts the high - speed rotational power input into low - speed and high - torque output. It is widely used in industries with high requirements for hygienic conditions, corrosion resistance, and transmission stability, such as food processing, beverage filling, pharmaceutical production lines, and water treatment equipment, providing precise and reliable power transmission solutions for various mechanical devices.

1.Unique Heat - dissipating Fin Design

Heat - dissipating fins are carefully designed on the stainless - steel housing, increasing the heat - dissipation area. This can quickly dissipate the heat generated during the operation of the reducer, effectively reducing the internal temperature and ensuring stable working performance during long - term continuous operation.

2.High - precision Gear Quenching Process

The gears are processed using a special quenching process. While maintaining a high - precision tooth profile, this process significantly improves the surface hardness and core toughness of the gears. This treatment enables the gears to have both good wear resistance and the ability to withstand large impact loads, ensuring the reliability of the transmission.

3.Customizable Shaft Extension Forms

It offers a variety of shaft extension forms for customers to choose from, such as single - shaft extension, double - shaft extension, and hollow - shaft. Moreover, the shaft extension dimensions can be customized according to the actual application scenarios and equipment connection requirements, enhancing the adaptability of the product to different devices.

4.Configuration of Magnetic Drain Plug

It is equipped with a magnetic drain plug. During the oil - draining process, the plug can adsorb the metal debris generated by gear wear in the lubricating oil, preventing these debris from causing secondary wear to internal components when the equipment runs again. This helps maintain the cleanliness of the lubricating oil and the clean environment inside the equipment.

5.Intelligent Oil - level Monitoring System

An intelligent oil - level monitoring system is built - in, which can monitor the oil - level of the lubricating oil inside the reducer in real - time. When the oil - level is too low, the system will automatically issue an alarm to remind the operator to refill the lubricating oil in time, avoiding equipment damage caused by lack of oil and ensuring that the equipment is always in a good lubrication state.

1.Ensure Continuous Equipment Operation

The unique heat - dissipating fin design and the intelligent oil - level monitoring system effectively reduce the risk of equipment failures caused by overheating and lack of oil. This ensures that the equipment can operate stably and continuously for a long time, reducing production interruptions caused by equipment failures and improving production efficiency.

2.Reduce Long - term Use Costs

The application of the high - precision gear quenching process and the magnetic drain plug greatly extends the service life of the gears and the lubricating oil, reducing the frequency of component replacement and lubricating oil addition. In the long run, this significantly reduces the equipment's use costs.

3.Facilitate System Integration

The customizable shaft extension forms enable this stainless - steel reducer to be easily integrated with various types of equipment. Whether it is the design and installation of new equipment or the upgrade and transformation of old equipment, it can be quickly adapted, providing great convenience for system integrators and equipment manufacturers.

4.Meet Diverse Production Requirements

Advantages such as different shaft extension forms, high - precision transmission, and stable operation enable the product to meet the power transmission requirements of various complex production processes and different equipment. It is widely used in multiple industries, demonstrating strong versatility.

5.Improve Equipment Management Efficiency

The intelligent oil - level monitoring system realizes real - time monitoring of the equipment's lubrication status. Coupled with the cleaning and maintenance of the lubricating oil by the magnetic drain plug, equipment managers can manage equipment maintenance work more scientifically and efficiently, prevent potential failures in advance, and optimize the equipment maintenance plan.

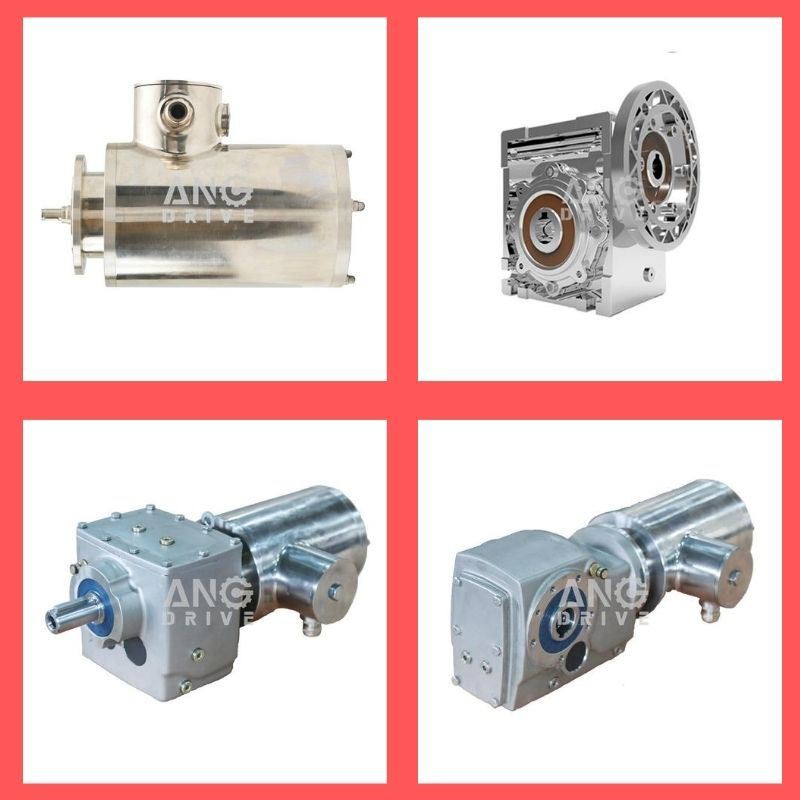

Family of stainless steel reductor and motor:

(1) Stainless steel electric motor: IEC motor, NEMA motor

(2) Stainless steel gear motors: helical type, worm type, bevel type

(3) Stainless steel worm reductor: IEC reductor, Inch reductor

(4) Stainless steel hypoid reductor

More products and information

Product page is only part of our products, if you do not find a suitable product, please contact our sales staff for consultation.

Hot Tags: stainless steel reductor, China, suppliers, manufacturers, factory, wholesale, price

Previous

NMRV Gear BoxNext

80mm Gear MotorYou Might Also Like

Send Inquiry