DC Motoreductor

Who We Are?

Hangzhou ANG Drive Co., Ltd. specializes in AC & DC motoreductor, electric motor, gearbox and controlling system developing, manufacturing, quality controlling, and trading.

What do We Make?

1. AC motor

2. DC motor

3. PM synchronous motor

4. Stepper motor

4. Worm motoreductor

5. Helical motoreductor

6. Hypoid motoreductor

7. Speed controller & driver & encoder

Why Choose Us

1. With 10 years experience, quality and delivery guaranteed.

2. With a manufacturing base in China, cost-effective.

3. One-stop driving solution available.

4. Flexible service available. MOQ is less than 10pcs, customized design, and urgent order solution.

Why usually use motoreductors instead of DC Motors?

Many battery-operated devices rely on DC motors for power. Because of their high shaft speeds-typically 1500-6000 RPM under load-DC motors are commonly paired with a gearbox. Without the gearbox, the shaft speed of DC motors often exceeds the requirements of most applications. Since many applications require a controllable shaft speed output, many DC motors are paired with mechanical gearboxes.

|

Typical Applications: |

|

|

Entertainment |

Gaming Machines, Kiddie Ride |

|

Lawn and Garden: |

Lawn Mowers, Snow Blowers, Trimmers, Leaf Blowers. |

|

Personal Care: |

Hair Cutting, Hair Care, Massagers. |

|

Power Tools: |

Drills and Drivers, Sanders, Grinders, Polishers, Saws. |

|

Camera and Optical: |

Video, Cameras, Projectors. |

Gears Harness the Power of DC Motors

The average shaft speed of a DC motor ranges between 1500 and 6000 RPM under load. These shaft speeds exceed the acceptable range for many applications, in most cases by a wide margin. To reduce shaft speeds, many DC motors are paired with a gearbox. This helps to reduce the motor's shaft speed, and increase the torque output of the motor. In most cases, torque is increased by the ratio of the gear reduction, minus any losses in the gearbox.

Operating Principle

Electromagnetic Principle: A DC motor works through the interaction between the magnetic field and the current-carrying conductor. When current flows through the armature coils, it creates a force that drives the motor's rotation.

Commutation: To keep the torque direction consistent while the armature rotates, DC motors need commutation. The commutator and brushes reverse the current direction in the armature coils, ensuring continuous rotation.

Components and Functions

Armature: The armature is the rotating part of the motor, consisting of an iron core and windings. When current passes through the windings, they interact with the magnetic field to generate torque, driving the load.

Excitation System: The magnetic field in a DC motor can be generated by either permanent magnets or electromagnets. Permanent Magnet DC motors use permanent magnets, while electromagnetically excited DC motors use current-carrying coils to produce the magnetic field.

Commutator and Brushes: The commutator is made of insulated copper segments and switches the connection between the armature and the power source. The brushes maintain contact with the commutator, transmitting current to the rotating armature.

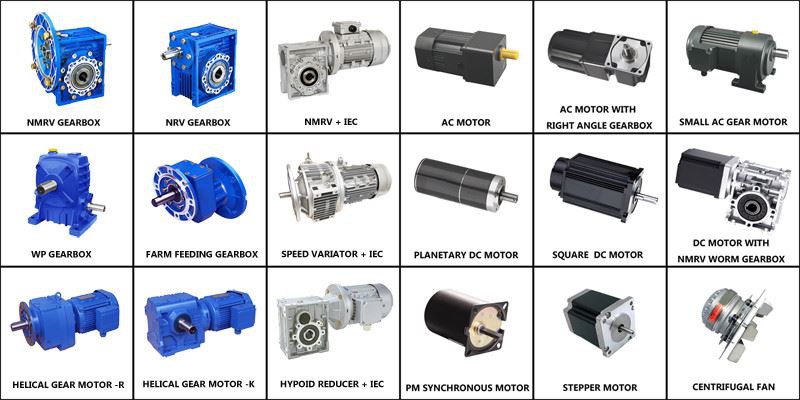

Some of the motoreductor are as per below photo:

Hot Tags: dc motoreductor, China, suppliers, manufacturers, factory, wholesale, price

Previous

Worm MotoreductorNext

ac motoreductorYou Might Also Like

Send Inquiry