ac motoreductor

Who We Are?

Hangzhou ANG Drive Co., Ltd. specializes in DC & AC motor eductor, electric motor, gearbox and controlling system developing, manufacturing, quality controlling, and trading.

Maintenance Tips for ac motoreductor

Daily Maintenance

Appearance Inspection:

Regularly inspect the motor's appearance for dust, oil buildup, or other debris. If present, clean the motor with a clean cloth to ensure proper heat dissipation. Also, check the motor housing for any damage, cracks, or deformation. Ensure the junction box is properly sealed. If any issues are found, address them promptly or replace the parts as necessary.

Connection Component Inspection:

Check if the bolts connecting the motor to the equipment are loose. If any are found to be loose, tighten them immediately to prevent vibration or detachment during operation, which could affect the normal function of the equipment. Additionally, inspect the power cables and ground wires for tight connections, wear, or aging. If any issues are detected, replace or repair them as needed.

Operating Condition Monitoring:

While the motor is running, listen for abnormal noises or vibrations. Under normal conditions, the bevel gear reducer motor should operate smoothly and quietly. If there are harsh, grinding, or other unusual noises, it could indicate issues such as gear wear or bearing failure. In such cases, stop the motor immediately for inspection. Also, monitor the motor's operating temperature-typically, the motor temperature should not be too high. If the motor is overheating, it could be due to excessive load, poor heat dissipation, or internal failure, and the cause should be promptly investigated.

Regular Maintenance

Lubrication System Maintenance:

Lubricating Oil Inspection: Every 2000-3000 hours of operation or 3-6 months, check the oil level and quality. The oil level should be within the range specified by the oil sight gauge. If the oil level is too low, top it up with the same type of oil. If the oil becomes black, thick, or contaminated, change the oil immediately.

Lubricating Oil Replacement: Generally, lubricating oil should be changed every 5000-10000 hours or 1-2 years. During the replacement, first drain the old oil, clean the oil tank and gears with a suitable cleaning agent, and then refill with the appropriate new oil.

Gear Inspection:

Periodically open the motor's inspection cover to check for gear wear. Inspect the gear teeth for signs of wear, cracks, or peeling, and measure the thickness of the teeth. Compare this with the original specifications to assess the wear level. Gears that show significant wear should be replaced promptly to maintain transmission accuracy and efficiency.

Bearing Inspection:

Check the bearing play using professional measurement tools. If the play exceeds the specified limit, it indicates that the bearings are worn and need to be replaced. Also, inspect the bearing lubrication. If the bearings are lacking oil or if the grease has deteriorated, add fresh lubricant or replace the grease as necessary.

Electrical System Inspection:

Regularly check the motor's insulation resistance by measuring the resistance between the motor windings and the housing, as well as between the windings themselves, using an insulation resistance tester. The resistance should meet or exceed the specified value. Inspect the motor's terminal connections to ensure they are clean, well-contacted, and free from oxidation or burn marks. If any issues are found, address them promptly or replace the damaged components.

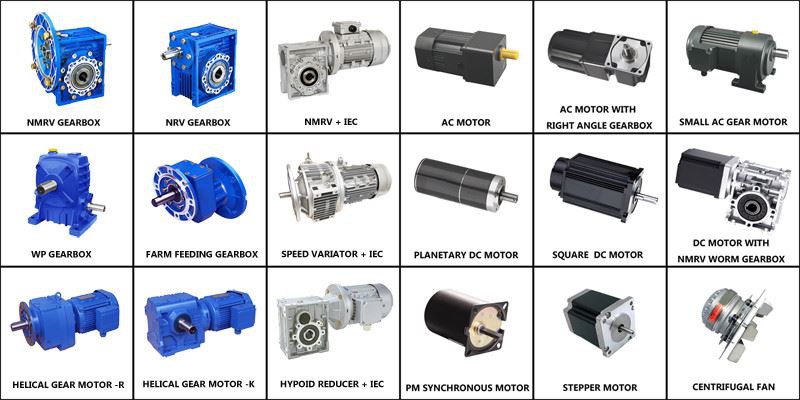

What do We Make?

1. AC motor

2. DC motor

3. PM synchronous motor

4. Stepper motor

4. Worm motoreductor

5. Helical motoreductor

6. Hypoid motoreductor

7. Speed controller & driver & encoder

Why Choose Us

1. With 10 years experience, quality and delivery guaranteed.

2. With a manufacturing base in China, cost-effective.

3. One-stop driving solution available.

4. Flexible service available. MOQ is less than 10pcs, customized design, and urgent order solution.

What Applications DO NOT Use ac motoreductor?

Due to the flexibility and widespread use of electric gear motors, it is actually easier to explore applications that DO NOT use them. Any application that requires high shaft speed will not benefit from the use of a gear motor. This includes fans, pumps, and engine starters. In these cases, the speed of the motor shaft rotation is the most important factor.

Gear motors are used in applications that require lower shaft speed and higher torque output. This describes a wide range of applications and scenarios, including many of the machines and equipment we interact with on a daily basis. From ATV wipers to hospital beds, security check conveyor to packaging equipment, paint mixers to juice dispensers, gear motors is used to power a significant number of machines and applications.

Some of the ac motoreductor are as per below photo:

Hot Tags: ac motoreductor, China, suppliers, manufacturers, factory, wholesale, price

Previous

DC MotoreductorNext

MotoreductorYou Might Also Like

Send Inquiry