DC Reducer Motor

Who We Are?

Hangzhou ANG Drive Co., Ltd. specializes in AC & DC reducer motor, electric motor, gearbox and controlling system developing, manufacturing, quality controlling, and trading.

What do We Make?

1. AC motor - induction & reversible

2. DC motor - brushed & brushless

3. PM synchronous motor

4. Stepper motor

5. Worm reducer motor- NMRV aluminum & WP iron casting housing

6. Helical reducer motor

7. Hypoid reducer motor

8. Controller device - speed controller & driver & encoder

Features for NMRV worm reducer motor:

Self-locking: For the place require for minor holding force, save the cost of the baking device, such as in slope conveyor.

Fast stop: The ordinary worm gear available in the market requires 5~10 seconds of stop time. But NMRV series product only needs 2~5 munites to reach of state of stillness.

Left-hand and right-hand worm

A right-hand helical gear or right-hand worm is one in which the teeth twist clockwise as they recede from an observer looking along the axis. The designations, right hand, and left hand, are the same as in the long-established practice for screw threads, both external and internal. Two external helical gears operating on parallel axes must be of opposite hands. An internal helical gear and its pinion must be of the same hand.

A left-hand helical gear or left-hand worm is one in which the teeth twist anticlockwise as they recede from an observer looking along the axis.

NMRV Worm Gearbox Components

1. Gearbox Housing

Function: The housing supports and protects the internal parts, providing a stable space for the components and preventing dirt and moisture from entering.

Material: Typically made of high-quality cast iron for strength and rigidity, ensuring stability during operation.

2. Worm and Worm Wheel

Worm Wheel

Function: Works with the worm to transfer and reduce speed, increasing output torque.

Material: Made from bronze, offering good wear resistance and corrosion resistance.

Worm

Function: Driven by the motor, it engages with the worm wheel to reduce speed and increase torque.

Material: Made of high-strength alloy steel for durability under heavy loads and frequent operation.

3. Bearings

Function: Support rotating parts, reduce friction, and ensure smooth operation.

Types: Deep groove ball bearings and tapered roller bearings are commonly used to handle both radial and axial loads.

FAQ

Q: Can you make the DC reducer motor with customization?

A: Yes, we can customize per your request, like the voltage, flange, shaft, configuration, material, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 20pcs for the beginning of our business.

Q: What is your lead time?

A: Standard products need 5-30days, a bit longer for customized products.

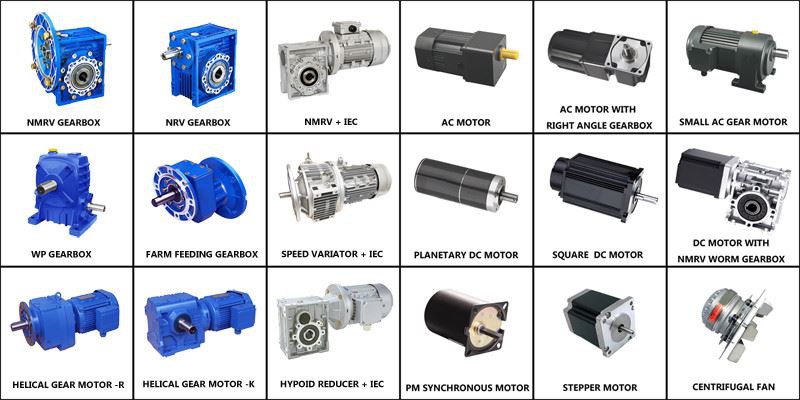

Some of the reducer motors are as per below photo:

Hot Tags: dc reducer motor, China, suppliers, manufacturers, factory, wholesale, price

Previous

Worm Gear Electric MotorNext

AC Reducer MotorYou Might Also Like

Send Inquiry